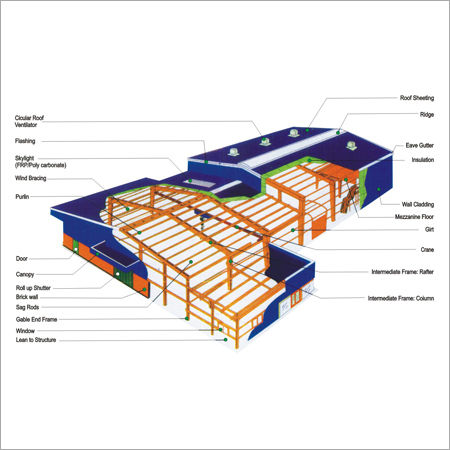

Pre Engineered Steel Buildings

Pre Engineered Steel Buildings Specification

- Door Material

- Steel or aluminum with powder coating

- Insulation

- PUF, glass wool, or rockwool insulation as required

- Window Material

- Aluminum frame with toughened glass

- Open Style

- Rolling, sliding or hinged

- Dimension (L*W*H)

- Customizable as per client requirements

- Connection

- Welded/bolted

- Wall Materials

- Insulated sandwich panels or galvanized steel sheets

- Material

- High tensile steel (Galvalume or Galvanized)

- Roof Material

- Color coated galvanized steel sheets

- Door

- Manually or electronically operated

- Window

- Aluminum or UPVC

- Window Style

- Sliding or fixed

- Roof Dead Load

- 0.25 0.5 kN/m

- Roof Live Load

- 0.57 kN/m

- Earthquake Intensity

- Designed up to Zone V (IS 1893)

- Color

- Standard industrial color options (grey, blue, white, customized)

- Use

- Warehouses, factories, workshops, commercial complexes

- Cladding Type

- Single skin or double skin with insulation

- Structure Type

- Modular portal frame structure

- Wind Resistance

- Designed for up to 180 km/h wind speed

- Foundation

- RCC pedestal or pile as per soil condition

- Surface Treatment

- Hot dip galvanized/Cold rolled with zinc coating

- Paint Coating

- Epoxy primer and polyurethane top coat

- Span

- Clear span up to 60m without intermediate columns

Pre Engineered Steel Buildings Trade Information

- Minimum Order Quantity

- 10000 Square Foots

- Supply Ability

- 300000 Square Foots Per Month

- Delivery Time

- 1 Months

About Pre Engineered Steel Buildings

We are renowned entity involved in offering Pre Engineered Steel Buildings fabrication services to our valuable clients. These services are offered with the support of our experienced professionals, who have vast knowledge of the domain and render these in compliance with predefined market norms. Our buildings are designed for withstanding adverse weather conditions. In order to ensure the best Pre Engineered Steel Buildings fabrication services, we utilize high-tech machines, tools and advanced technologies. Moreover, the fabricated building is highly treasured for its durability, reliability and high performance level as per the prevailing safety standards.

Product Details

|

Material |

Steel |

|

Material |

Steel |

|

Built Type |

Prefab |

|

Feature |

Easily Assembled |

|

Wind Pressure |

120 |

|

Storage |

As per required |

|

Commercial |

industrial |

Superior Structural Design

Our pre-engineered buildings utilize a modular portal frame structure, offering clear spans up to 60 meters without the need for intermediate columns. This design maximizes usable floor space, making it ideal for large-scale industrial and commercial operations. A robust RCC pedestal or pile foundation, chosen based on soil evaluation, ensures structural stability and longevity.

Advanced Weather & Seismic Protection

Engineered to withstand wind speeds up to 180 km/h and conforming to Earthquake Zone V standards (IS 1893), these buildings provide dependable safety and resilience. The exterior features epoxy primer and polyurethane top coats, along with hot dip galvanized or cold rolled zinc-coated surfaces for extraordinary weather resistance.

Flexible Cladding & Custom Finish Options

Clients can choose single skin, double skin with insulation, or insulated sandwich panel cladding for optimized thermal performance. With a broad range of color-coated galvanized steel sheets and standard or customized color options, the buildings aesthetic can be tailored to match specific branding or operational needs.

FAQs of Pre Engineered Steel Buildings:

Q: How is the modular portal frame structure advantageous for pre-engineered steel buildings?

A: The modular portal frame structure allows for large clear spans of up to 60 meters without intermediate columns, providing wide, unobstructed interiors. This is particularly beneficial for industrial and warehousing applications that require flexible space utilization.Q: What steps are involved in the installation process of these steel buildings?

A: The process includes site evaluation, design customization, foundation laying (RCC pedestal or pile), fabrication with high-tensile galvanized steel, onsite assembly via welded or bolted connections, and final fitting of cladding, insulation, doors, and windows. Attention is given to precise manufacturing for quick installation and structural reliability.Q: When should I consider using a double skin cladding with insulation?

A: Double skin cladding with insulation is recommended when temperature control, energy efficiency, and sound reduction are important, such as in refrigerated warehouses, manufacturing units, or offices within industrial complexes. The insulation options include PUF, glass wool, or rockwool, tailored to project needs.Q: Where are these pre-engineered steel buildings typically used?

A: These buildings are widely employed in warehouses, factories, workshops, commercial complexes, and other sectors requiring expansive, customizable, and robust structures. Their adaptability also makes them suitable for export and service provider projects across India and abroad.Q: What type of maintenance do these buildings require to ensure durability?

A: Maintenance is minimal due to the use of high-quality coatings like epoxy primer and polyurethane top coat, along with hot dip galvanized or zinc-coated steel. Routine checks on cladding, joints, and painted surfaces will help prolong lifespan and preserve structural integrity.Q: What benefits do pre-engineered steel buildings offer over conventional buildings?

A: Benefits include faster construction, customizable dimensions, superior wind and earthquake resistance, energy-efficient insulated cladding, and lower long-term maintenance. The manufacturing precision enhances structural strength and allows for flexible expansion when required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Engineering Building Category

Mezzanine Floors

Price Range 50000.00 - 500000.00 / Square Foot

Minimum Order Quantity : 10000 Square Foots

Material : Other , Steel, Mild Steel

Window : Other, Standard / Customized

Window Style : Other, Sliding / Fixed

Steel Structures

Price Range 50000.00 - 500000.00 / Square Foot

Minimum Order Quantity : 10000 Square Foots

Material : Other , Q235/Q345 Steel

Window : Other, Single/Double Glazed

Window Style : Other, Sliding/Fixed

Pre Engineered Building Systems

Price 1500 INR / Square Foot

Minimum Order Quantity : 10000 Square Foots

Material : Steel

Window : Other

Window Style : Sliding Window

Commercial Prefab Buildings

Price 88 INR / Kilograms

Minimum Order Quantity : 10000 Square Foots

Material : Steel

Window : Other

Window Style : Sliding Window

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS