Primary Framing System

Price 3500 INR/ Piece

Primary Framing System Specification

- Humidity Range

- Suitable for varied environments

- Application

- Warehouses, Factories, Commercial Sheds

- Surface Finish

- Painted or Galvanized

- Technology

- Computer Aided Design (CAD) & Fabrication

- Accessories

- Bolts, Fasteners, Base Plates

- Automation Grade

- Manual

- Coverage Area

- Custom as per Building Design

- Features

- Corrosion Resistant, High Load Capacity, Precision Fabricated, Easy Installation

- Material

- High Strength Structural Steel

- Type

- Primary Framing System

- Capacity

- Custom Designed (Based on project requirements)

- Usage

- Industrial and Commercial Buildings

- Function

- Structural Load Bearing

- Load Resistance

- Designed per seismic and wind load requirements

- Span Range

- Up to 60 meters (customizable)

- Design Standards

- IS 2062 / ASTM / BIS Standards

- Welding

- MIG/MAG Automated Welding

- Corrosion Protection

- Epoxy Coating or Hot Dip Galvanized

- Thickness

- As per engineering specification (typically 5mm to 25mm)

Primary Framing System Trade Information

- Minimum Order Quantity

- 10000 Square Foots

- Supply Ability

- 300000 Square Foots Per Month

- Delivery Time

- 2 Days

About Primary Framing System

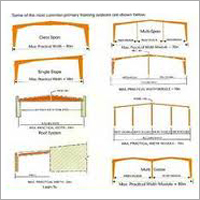

Primary Framing System

Our enterprise has gained recognition in the industry for offering an excellent quality assortment of Primary Framing System. This system is extensively used for different industrial applications. The offered system is manufactured using high grade raw materials and advanced techniques. This system is widely demanded owing to its attributes like corrosion resistant finish, high tensile strength, purity, robustness and durable finish standards. Further, this Primary Framing System is available with us in different lengths and thicknesses as per the specific needs of clients.

Product Details

|

Surface Finish |

Polished |

|

Built Type |

Panel Build,Prefab |

|

Feature |

Easily Assembled,Eco Friendly |

|

Material |

MS etc |

Customizable Span and Capacity

Our Primary Framing System provides customizable span lengthsup to 60 metersto suit project-specific requirements. The systems load-bearing capacity is engineered to match the unique needs of industrial and commercial buildings, accommodating both heavy and dynamic loads efficiently. Advanced CAD-based design ensures structural precision and long-term resilience.

Durability and Corrosion Protection

Fabricated from high-strength structural steel, these primary frames are treated with either epoxy coatings or hot-dip galvanization. Such surface finishes enhance durability by shielding against corrosion, making the system suitable for installation in a variety of environmental conditions, including high-humidity locations.

Modern Engineering and Precision Fabrication

Utilizing advanced computer-aided design and automated MIG/MAG welding, our framing systems deliver exceptional precision and structural integrity. Every structural element conforms to IS 2062/ASTM/BIS standards, optimizing safety and ensuring compliance with seismic and wind load requirements common in industrial and commercial applications.

FAQs of Primary Framing System:

Q: How is the span capacity of the Primary Framing System tailored to individual projects?

A: Each Primary Framing System is custom-designed using CAD technology to achieve the required span, up to 60 meters. Engineers analyze your projects specific load and usage requirements, allowing for precise span and capacity adjustment to maximize efficiency and safety.Q: What standards and materials are used in the construction of this framing system?

A: The framing system is fabricated from high-strength structural steel, meeting IS 2062, ASTM, and BIS standards. This ensures consistent quality and structural integrity, suitable for demanding industrial and commercial applications.Q: When should I choose a hot dip galvanized finish over epoxy coating?

A: Hot dip galvanization is typically chosen for projects in highly corrosive or humid environments, providing robust, long-lasting protection. Epoxy coating offers effective resistance for less severe conditions or where aesthetic finishes are preferred.Q: Where can the Primary Framing System be installed?

A: These systems are flexible and designed for a variety of industrial and commercial settings, including warehouses, factories, and commercial sheds. The systems adaptability suits both new constructions and expansions across diverse locations in India.Q: What is the installation process for the framing system?

A: Installation is streamlined using precision-fabricated components and accessories like bolts, fasteners, and base plates. The manual, yet efficient installation process ensures structural accuracy and minimizes construction time.Q: How does the system benefit building performance and longevity?

A: The systems high load-bearing capacity, corrosion-resistant surface treatment, and tailored design extend building life and reduce maintenance. Precision fabrication ensures safety, while easy installation supports quicker project completion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS