Secondary Framing System

Secondary Framing System Trade Information

- Minimum Order Quantity

- 10000 Square Foots

- Supply Ability

- 300000 Square Foots Per Month

- Delivery Time

- 2 Week

About Secondary Framing System

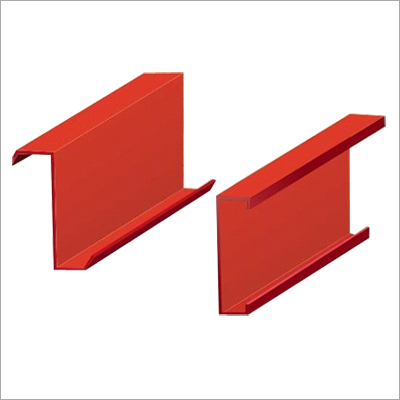

Secondary Framing System "C"&"Z" Parlin

With rich industry knowledge and experience, we are able to manufacture, trader and supply Secondary Framing System that is used to make the frames for buildings and other structures. The offered system is extensively appreciated by our clients due to the durable finish standards, dimensional accuracy, high strength, robust construction and rust resistance. This system is manufactured with utmost precision using high grade stainless steel to meet the set industry standards. We are offering Surface Treatment of "C" & "Z" Profiles for framing systems made of cold formed steel coils. Ranging from galvanization to coating treatment, we offer varied solutions to profiles that are in line with the test requirements of IS: 4777 and IS: 2074. We also offer coating treatments on these frames for enhancing their serviceability. Available in various sizes and finishes, this Sink Drain Coupling can also be customized as per our clients requirements.

We offer the following treatments to our clients:

- Degreasing, phosphating and primer finishing with zinc chromate red oxide paint

- Special corrosion treatment for countering adverse climatic conditions

- Galvanized steel coating in 120 GSM/175GSM and 275GSM as per requirement

Product Details:

|

Shape |

Z Shape |

|

Zinc Coating |

20-275 g/m2 |

|

Mid Flange |

60 mm |

|

Thickness |

1.4-3.2 mm |

|

Brand |

SAIL,ESSAR,JSW,TATA |

|

Position |

Interior, Exterior |

|

Material |

HR/CR |

|

Flange (mm) |

30~80MM |

Superior Corrosion Protection

Each secondary framing component is treated with a galvanized coating, resulting in excellent resistance against corrosion. This not only prolongs the lifespan of the system but also ensures reliable structural integrity, even in demanding environmental conditions. Our commitment to quality extends to every stage of manufacturing.

Effortless Installation

Designed for practicality and efficiency, the system utilizes simple bolted connections. This allows for swift assembly on-site, reducing both installation time and the need for specialized labor. All required accessories, including bracing, connecting plates, and fasteners, are provided to facilitate a seamless process.

FAQs of Secondary Framing System:

Q: How is the corrosion resistance of this secondary framing system achieved?

A: The system achieves excellent corrosion resistance through a robust galvanized coating, which acts as a protective barrier against rust and environmental damage.Q: What standards are used in manufacturing the secondary framing system?

A: Our framing system is manufactured according to IS 277 and ASTM A653 standards, ensuring quality, durability, and consistent performance.Q: When can color coating options be requested for the framing system?

A: Color coating options are available at the customers request and can be selected during the order placement process to suit specific aesthetic or functional needs.Q: Where can this secondary framing system be used?

A: The system is engineered for use in commercial, industrial, and infrastructure projects across India, offering flexible solutions wherever robust secondary framing is needed.Q: What is the process for installing the secondary framing system?

A: Installation involves assembling the system using simple bolted connections, which allows for quick, straightforward setup with reduced labor requirements.Q: How is the load-bearing capacity determined for each project?

A: Load-bearing capacity is engineered to match the unique requirements of each project, following a thorough analysis of the intended application and structural demands.Q: What are the key benefits of using your secondary framing system?

A: Key benefits include superior corrosion resistance, easy installation, adherence to international standards, customizable options, and comprehensive accessory support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS